SUMMARY

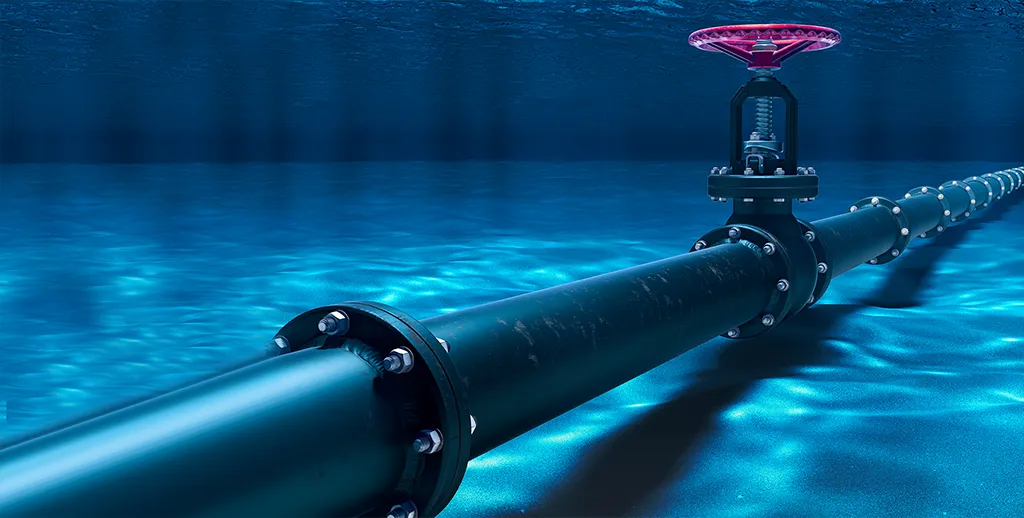

Royalpoxy UW 410 is a high-performance underwater epoxy coating designed to protect submerged and wet surfaces from corrosion in demanding marine environments. Engineered for direct application onto wet, oily, or fully submerged surfaces, this innovative epoxy displaces water and oil for a reliable bond on steel, concrete, and other metals. Suitable for offshore structures, jetty supports, and boat hulls, Royalpoxy UW 410 eliminates the need for dry-docking and extensive prep work, curing efficiently underwater and simplifying maintenance tasks while reducing downtime. For durable, versatile protection, Royalpoxy UW 410 is the premier solution for long-lasting underwater corrosion resistance.

Product Overview

Royalpoxy UW 410 is a cutting-edge underwater epoxy coating designed for direct application to wet, oily, or fully submerged metal and concrete surfaces. Engineered for marine environments and submerged structures, Royalpoxy UW 410 forms a robust, long-lasting barrier against corrosion. Its advanced formula displaces water and oil, allowing strong adhesion to stainless steel, carbon steel, and other metals.

This innovative epoxy coating can be applied directly underwater using a brush or roller, reducing downtime and eliminating the need for dry-docking or hot work. With Royalpoxy UW 410, maintenance becomes safer, faster, and more efficient, extending the lifespan of assets across industries.

Key Features and Benefits

Versatile Application on Submerged and Wet Surfaces

Royalpoxy UW 410 can be used on a variety of submerged assets, including offshore jacket legs, port and jetty support structures, and marine vessels. Whether surfaces are fully submerged, wet, or cold, Royalpoxy UW 410 provides consistent, reliable protection.

Minimal Preparation with High Adhesion

Packaged in pre-measured containers for optimal mixing, Royalpoxy UW 410 is easy to prepare and apply. Its strong adhesion enables it to bond effectively to surfaces prepared with power tools or high-pressure water jets, making it highly cost-effective and labor-efficient.

Excellent Corrosion Protection

Built to withstand harsh underwater conditions, this epoxy coating displaces moisture and oil, ensuring durable protection against corrosion, abrasion, and other forms of environmental wear.

Curing Underwater

Application Process

Preparation and Mixing

Each set of Royalpoxy UW 410 is pre-packaged in the correct mixing ratio. Simply pour the contents of Part B into the container labeled Part A, then mix thoroughly for approximately one minute until the blend appears homogeneous.

Underwater Application

After mixing, Royalpoxy UW 410 is ready for immediate use. It can be applied directly onto fully submerged surfaces using a brush or roller, just as you would on a dry substrate.

Application on Wet or Cold Surfaces

Technical Specifications

Recommended System

Two coats of Royalpoxy UW 410 at 125 microns (dft/wft) each, ensuring optimal corrosion protection.

Surface Compatibility

Works well on wet, oily, or underwater metal surfaces and displaces moisture and contaminants upon contact.

Uses

Why Choose Royalpoxy UW 410?

Royalpoxy UW 410 stands out due to its unique application flexibility—it functions like a traditional epoxy coating while offering greater versatility in application conditions. With a single solution for both in-water and on-land applications, this coating reduces the need for dry-docking and allows maintenance teams to maximize uptime.