What causes Paint Defects?

a. Formulation of the paint

b. Surface preparation

c. Application

d. Drying & curing times

e. Conditions & Environmental exposure

Common Paint Defects

a. Blistering

Probable Causes: Formation of bubbles like shapes on the painted surface is known as blistering. The primary cause of this defect is water vapor. When water vapor trapped under the paint layer, it creates bubbles under the film of paint.

Prevention: Ensure correct surface preparation and application. Apply a suitable coating system after testing for water vapor. Consider the possibility of the different causes in the particular environment.

b. Blooming (Blush)

Probable Causes: Formation of dull patches on the painted surface is known as blooming. The primary cause of this defect is poor quality of paint and improper ventilation causing it to be exposed to condensation or moisture during curing, especially at low temperature.

Prevention: Apply and cure coating systems under correct environmental conditions and follow the manufacturer’s recommendations.

c. Fading

Probable Causes: When there is a gradual loss of colour from the pained surface, it is known as fading. The main cause of this defect is the reaction of sunlight on pigments of paint. This may be due to incorrect pigmentation, use of non-light-stable organic pigments as well as porous substrate.

Prevention: Use correct coating systems that resist ultraviolet light and fading. Use a coating with light- stable pigments.

d. Flaking

Probable Causes: In this type of defect, some portion of the paint does not properly adhere to the surface; resulting flaking off of the paint layer. It can be due to incorrect paint system used – usually due to no or incorrect pre-treatment used for certain substrates. It may also be due to poor application techniques or the differential expansion and contraction of paint and substrate, for example, wood. Another possible reason may be due to the aging of the paint system.

Prevention:Use correct coating system and pre-treatment.

e. Grinning

Probable Causes: If the thickness of the final coat of paint becomes very thin, the background can be seen clearly. This is known as grinning. Poor application technique is the main cause of this defect or due to strong colour of primer/undercoats.

Prevention: Apply adequate dry-film thickness between individual coats. Use opaque coatings with good opacity.

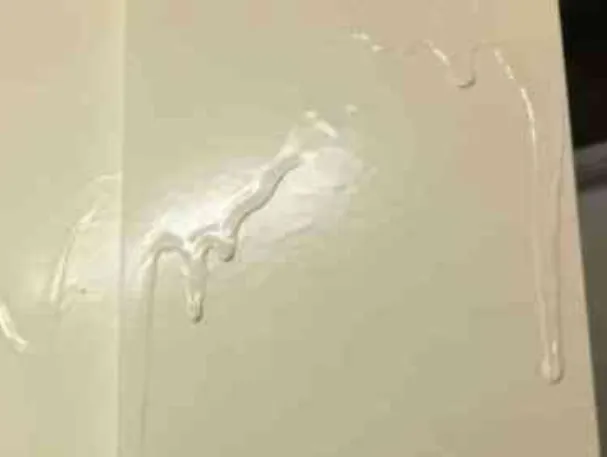

f. Running

Probable Causes: This type of defect is seen when the surface to be painted is very smooth. In case of smooth surface, the paint runs back and leaves small areas of surface uncovered. Overapplication of paint, excessive use of thinners, incorrect (or lack of) curing agent, or poor application technique may be the main causes.

Prevention: Use correct application techniques and apply at the recommended dry-film thickness.

g. Sagging

Probable Causes: This type of defect is more prominent when a thick layer of paint is applied on a vertical or inclined surface. Overapplication of paint, excessive use of thinners, incorrect (or lack of) curing agent, or poor application techniques are the probable causes of this defect.

Prevention: Use correct application techniques with suitably formulated products.

h. Wrinkling

Probable Causes: This type of defect is more prominent when a thick layer of paint is applied on a horizontal surface. Usually due to the initial formation of a surface skin with solvent-based paints. Can arise from overcoating before the previous coat has adequately hardened.

Prevention: Use correct coating specification and materials, and ensure adequate mixing, application, and curing by following the paint supplier’s recommendations.